We are Singapore's first based drone company to have received the Lloyd’s Register (LR) certification.

The Lloyd's Register (LR) certification will allow us to conduct surveys using the Remote Inspection Technique on the structure of ships and mobile offshore units via unmanned aerial vehicle (UAV)

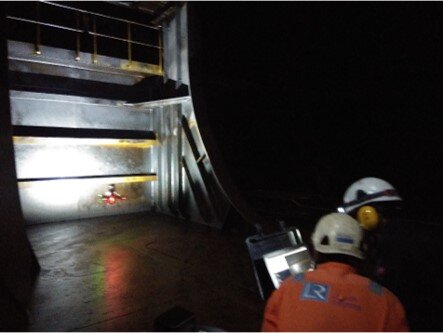

We have been providing Confined Space Inspection since 2017, our pilots are professional, engineering-centric and experienced with multiple projects under their belt.

Avetics is spearheading the application of drone services for industrial inspections in Singapore and Malaysia.

We provide peace of mind to our engineering clients - ensuring the job is done safely and effectively.

Fast, cost-effective and low-risk

Why use Drone?

Conventional methods of storage/vessel tank inspection require a significant amount of money and time. Most of which are contributed by logistics & equipment planning, manpower and safety training.

With the advancement of drone inspection, confined space inspection can be done in a faster, safer, and more cost-efficient method.

Achieve images all the way up to the top in 30 minutes and inspect the entire tank in a few hours to decide if scaffolding is really necessary.

Benefits:

Time Efficient

Eliminate time and costs required to erect scaffolding inside tanks. Get imagery of high areas in 30 minutes

Cost Savings

Inspect the entire tank in a few hours and decide if scaffolding is really necessary.

Cutting cost on logistics for scaffolding and manpower.

scaffolding in storage tank

Worker climbing up to great height to do inspection

Reduce Health & Safety Hazards

Cuts out the need for people to be placed at a height, avoiding potential danger to personnel.

Most storage/vessel tanks environment are toxic and flammable, which is hazardous to employees if they stay inside for a long period of time.

We can eliminate these risks with efficient drone inspection.

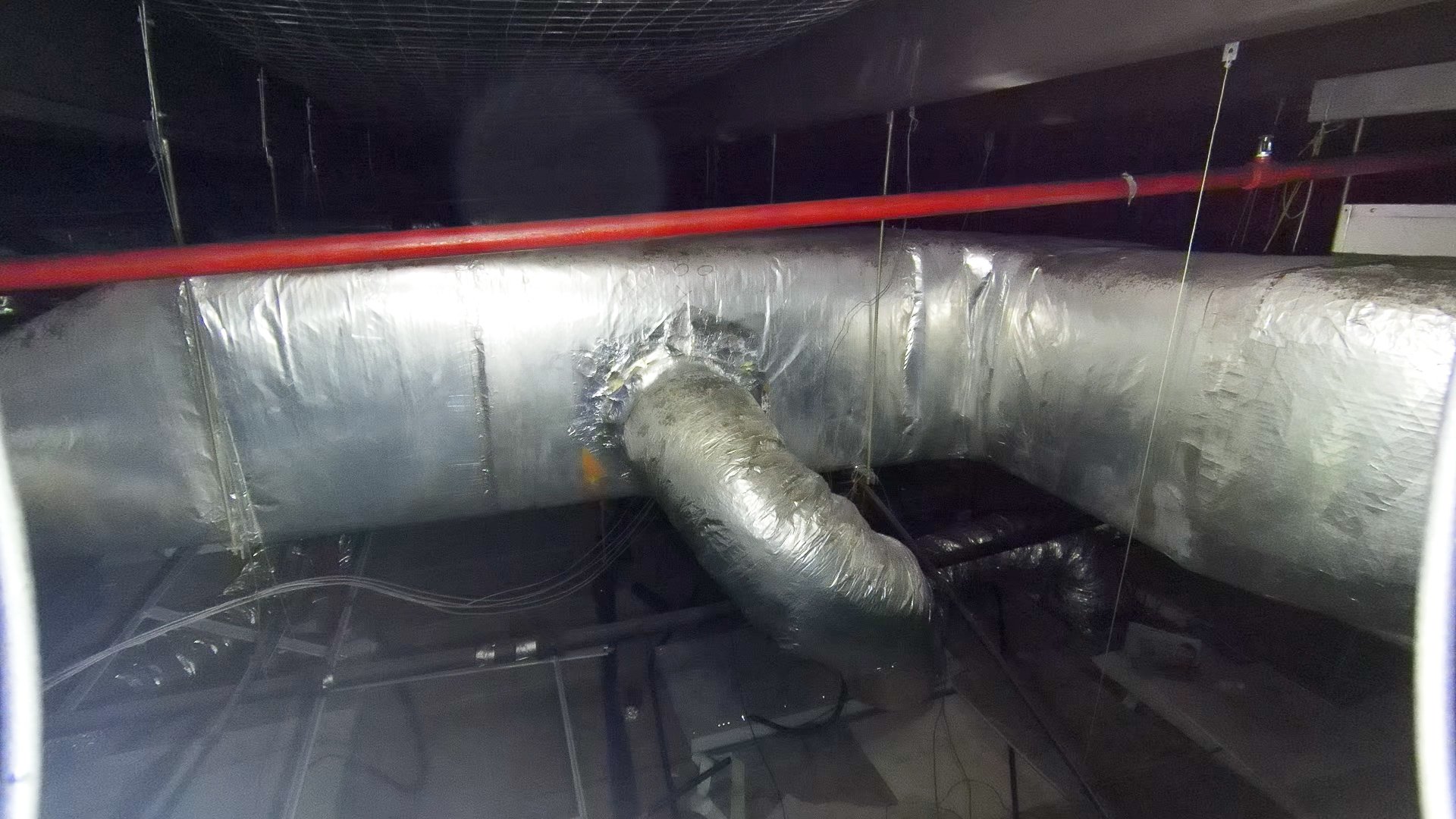

Custom In-Tank Drone - Made to operate reliably in a metal tank and confined spaces

Drones and Robots customized by our professional engineers are capable to perform inspections in confined spaces such as LNG tanks, Vessel tanks, and Storage tanks.

Our drones and robots are designed to equip with multiple sensors to conduct various inspections.

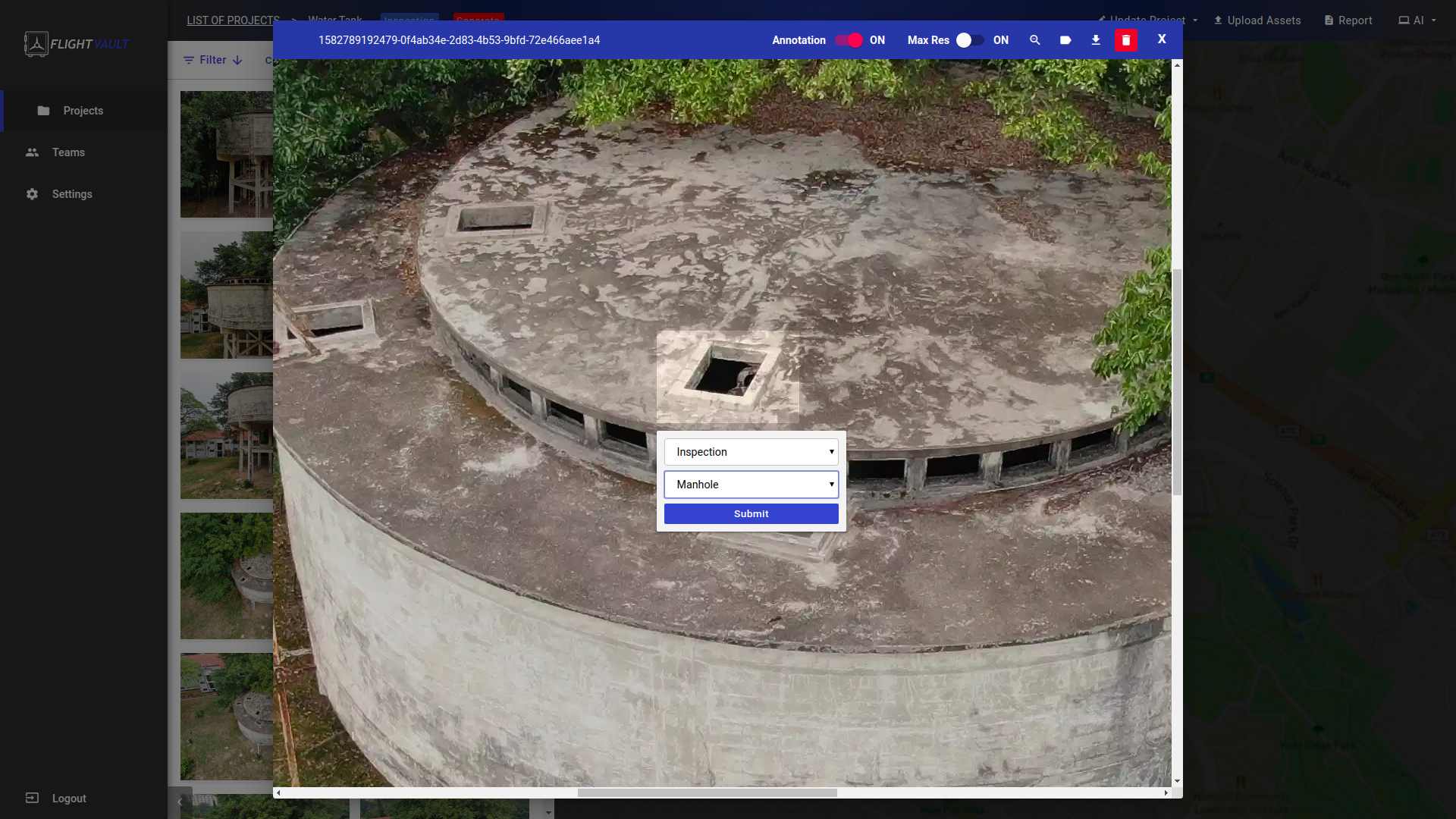

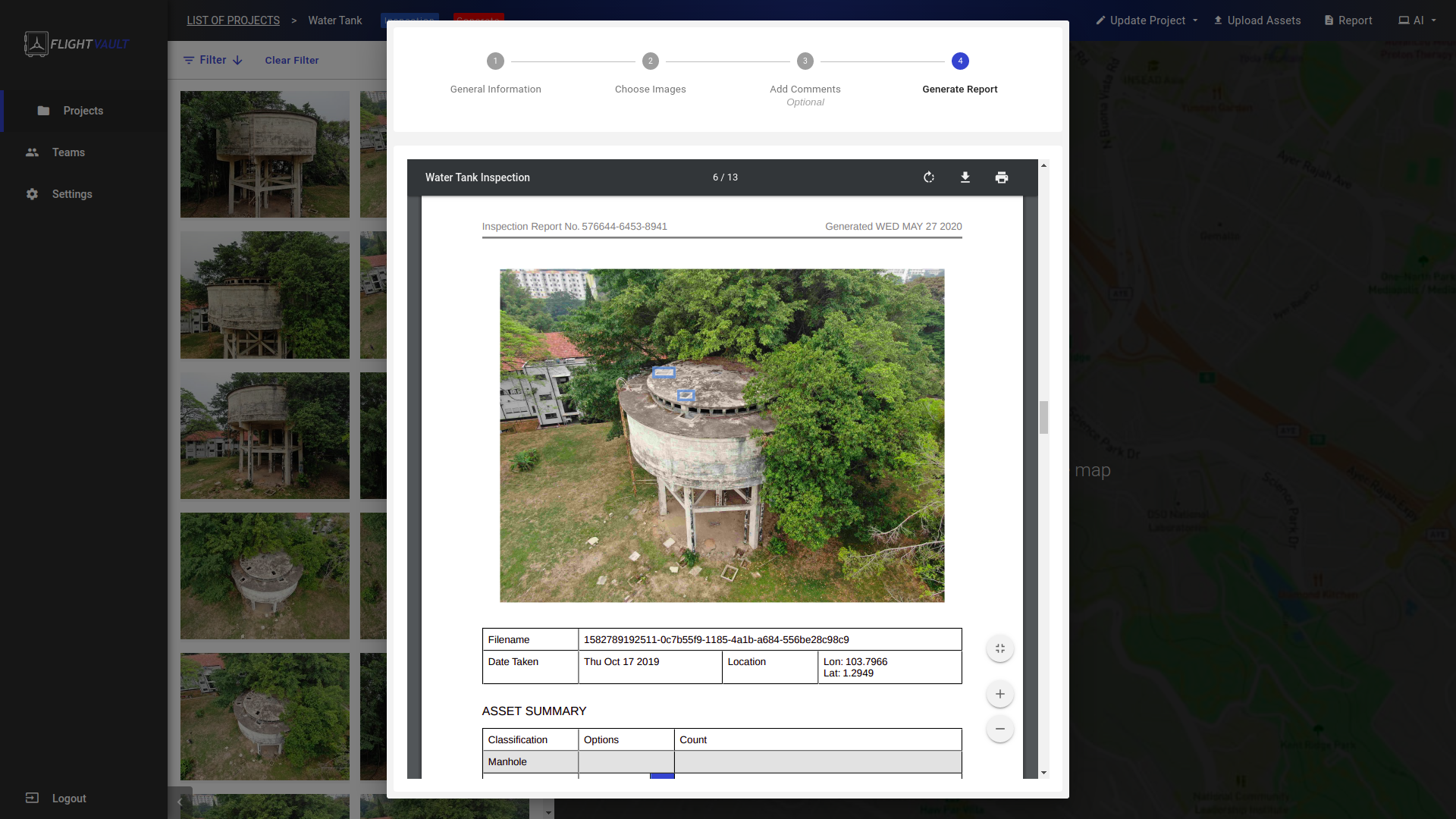

Utilise our own intelligent AI data management software: Flightvault

Flightvault is an easy-to-use drone data management system. Enable organising multiple drone photos and videos a breeze. It allows 4G upload of photos in the field and automated AI analysis. Reports are then generated all within minutes.

Data is sent from the field team directly to the webserver.

System auto analyses defects. Inspector then checks and prepares a report.

Field team can log in to view the report and location of defects and carry out the repairs accordingly.

For more information about our software: